Eddy Current Testing Level 2 [surface/tube] (as per SNT TC 1A Employer Written practice)

In eddy current testing, a coil carrying an AC current is placed close to the specimen surface, or around the specimen. The current in the coil generates circulating eddy currents in the specimen close to the surface and these in turn affect the current in the coil by mutual induction. Flaws and material variations in the specimen affect the strength of the eddy currents.

The presence of flaws etc is therefore measured by electrical changes in the exciting coil. Both voltage and phase changes can be measured, but some simpler instruments measure only the voltage changes.

The strength of the eddy currents produced depends on the:

a) electrical conductivity of the specimen;

b) magnetic permeability (for a ferromagnetic specimen);

c) stand-off distance between the specimen and coil;

d) AC frequency used in the exciting coil;

e) dimensions of the coil and specimen;

as well as the presence of flaws, and much of the success of eddy current testing depends on separating the effects of these variables. Most eddy current instruments require calibration on a set of test specimens and the flaw sensitivity can be very high.

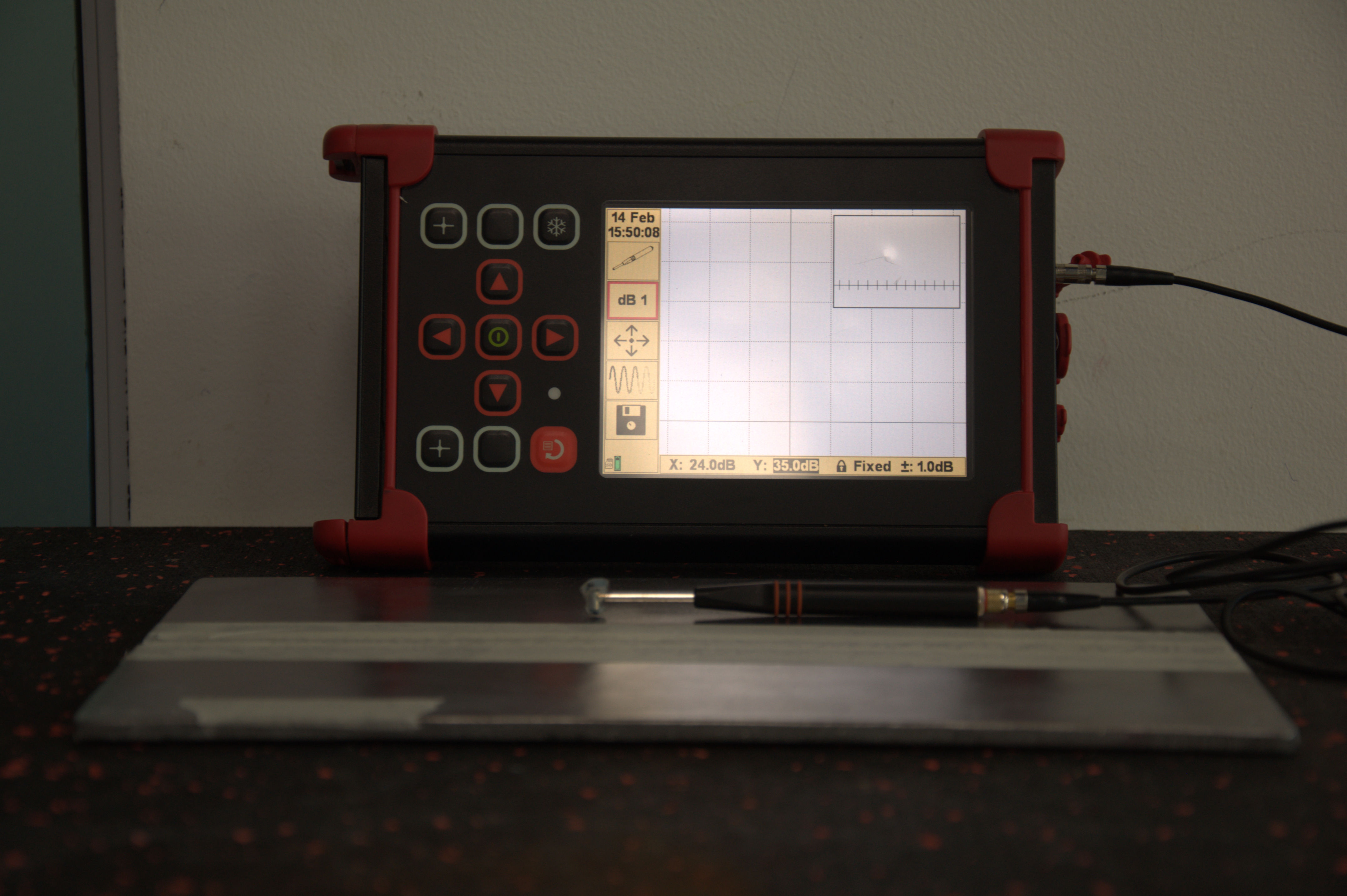

Equipments vary from simple portable meter read-out instruments to more complex oscilloscope read-out displaying both phase and voltage; recently the outputs have been digitised to produce fully-automated computer-programmed equipment with monitored outputs for high-speed testing.

Applications vary from crack detection, to the rapid sorting of small components for either flaws, size variations or material variation. Many applications are to bar, tube and wire testing. Metal sorting is also a common application of eddy current testing.

Eddy Current Testing - Level II

1.0 Review of Electromagnetic Theory

1.1 Eddy current theory

1.2 Types of eddy current sensing probes

2.0 Factors that Affect Coil Impedance

2.1 Test part

2.1.1 Conductivity

2.1.2 Permeability

2.1.3 Mass

2.1.4 Homogeneity2.2 Test system

2.2.1 Frequency

2.2.2 Coupling

2.2.3 Field strength

2.2.4 Test coil and shape

2.2.5 Hall elements

3.0 Signal-to-Noise Ratio

3.1 Definition

3.2 Relationship to eddy current testing

3.3 Methods of improving signal-to-noise ratio

4.0 Selection of Test Frequency

4.1 Relationship of frequency to type of test

4.2 Considerations affecting choice of test

4.2.1 Signal-to-noise ratio

4.2.2 Causes of noise

4.2.3 Methods to reduce noise

4.2.3.1 DC saturation

4.2.3.2 Shielding

4.2.3.3 Grounding

4.2.4 Phase discrimination

4.2.5 Response speed

4.2.6 Skin effect5.0 Coupling

5.1 Fill factor

5.2 Lift off6.0 Field Strength and its Selection

6.1 Permeability changes

6.2 Saturation

6.3 Effect of AC field strength on eddy current testing7.0 Instrument Design Considerations

7.1 Amplification

7.2 Phase detection

7.3 Differentiation of filtering